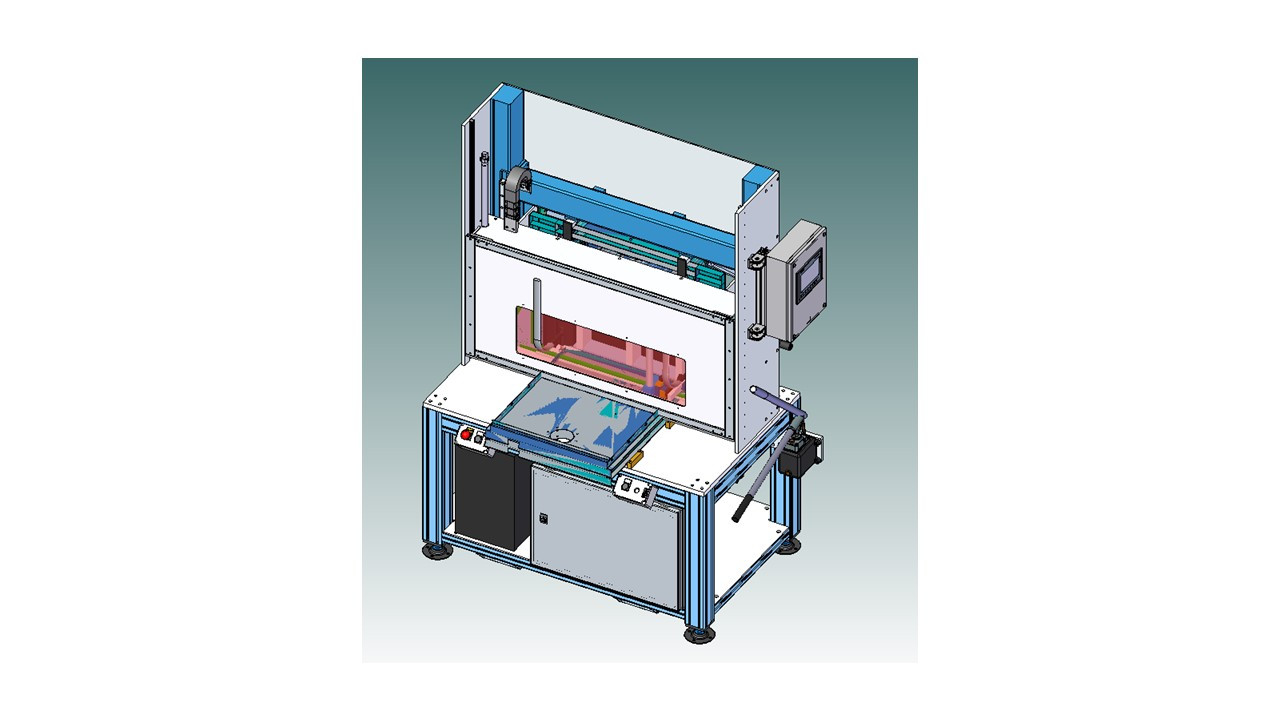

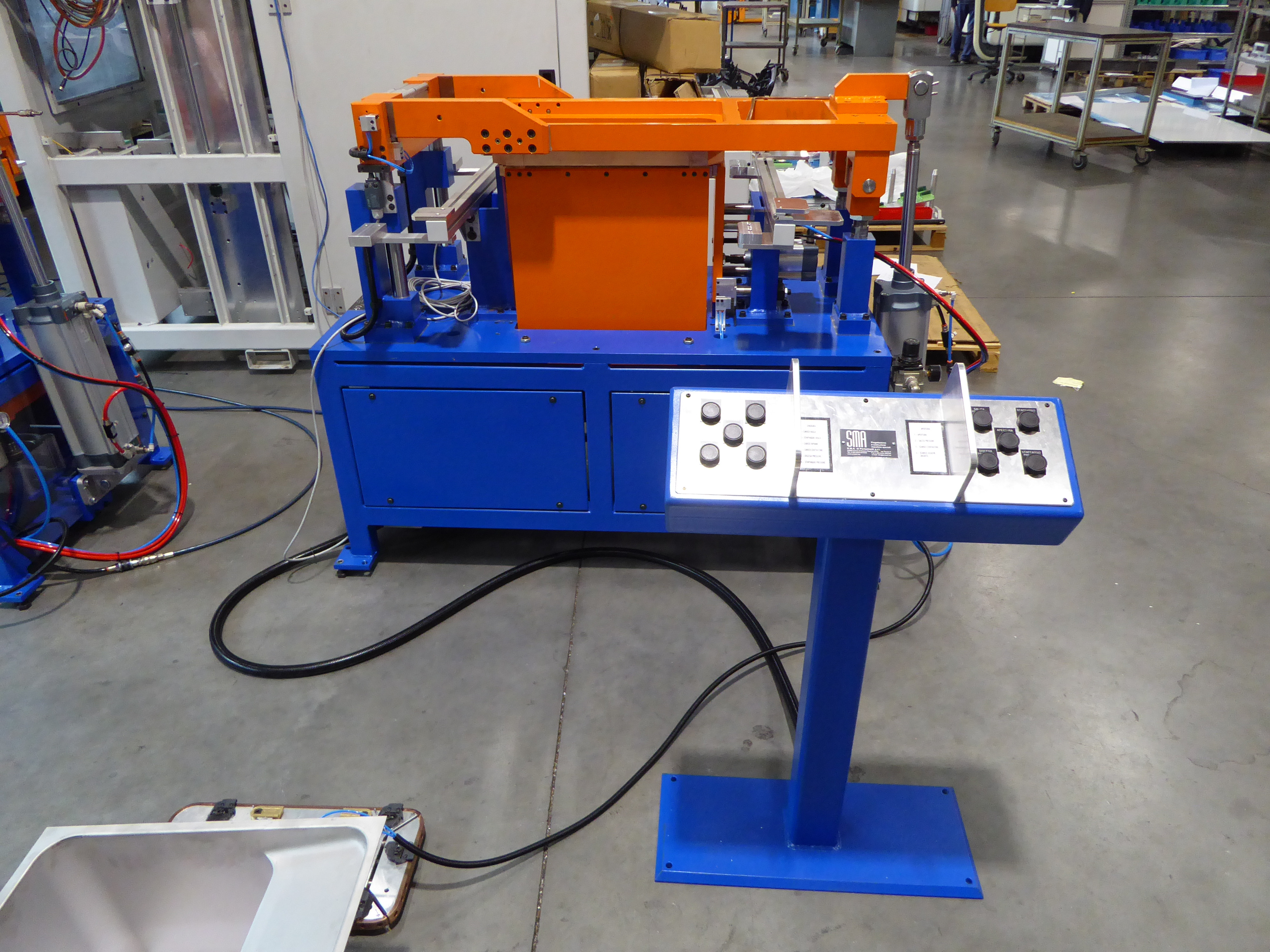

Robot welding equipment for ovens

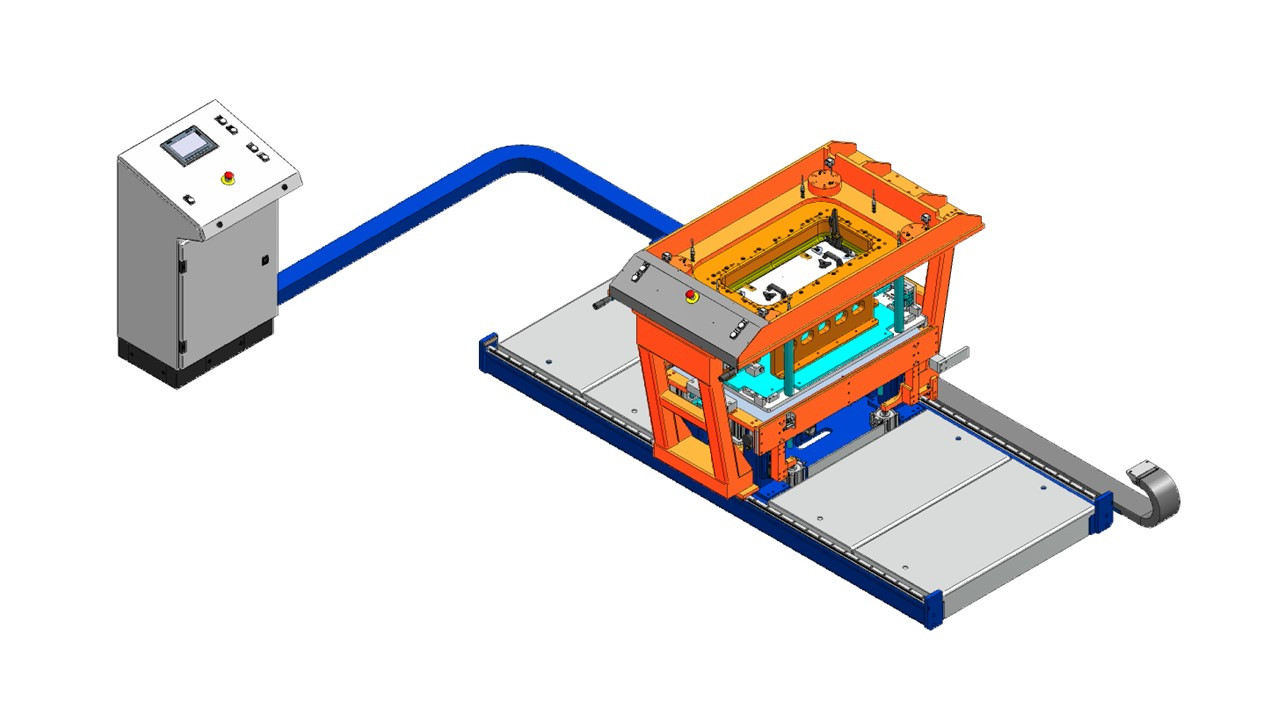

Equipment for robotic TIG welding of the chamber and bottom of professional catering ovens.

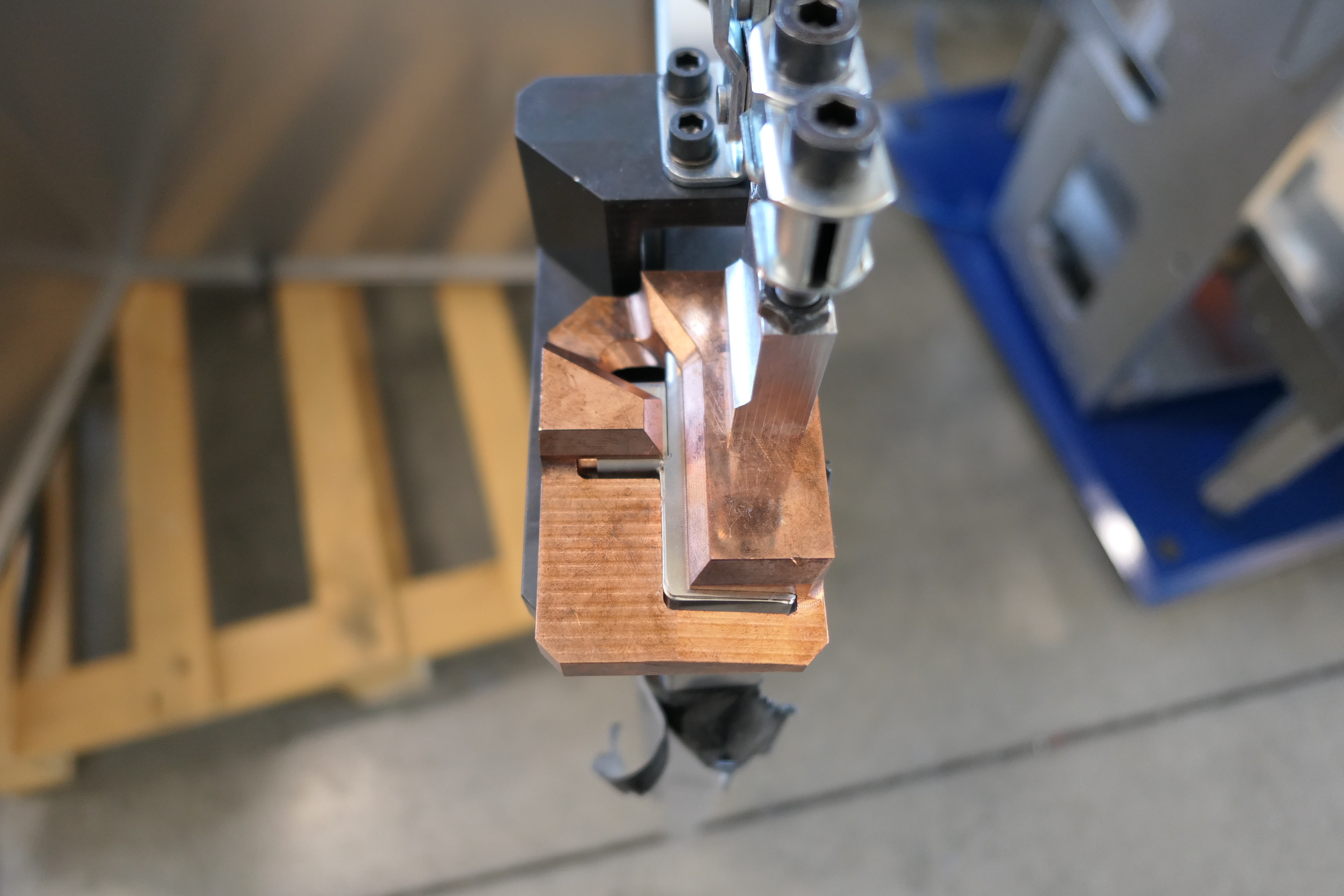

precise mating of components to ensure maximum accuracy and process repeatability

effective dissipation of heat generated during TIG welding, preventing thermal transfer to the sheet and ensuring absence of distortions

rapid setup of the equipment according to the model to be processed, via quick setup without the use of tools

interface with welding robot

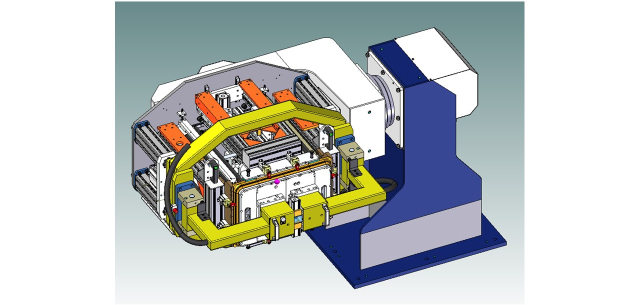

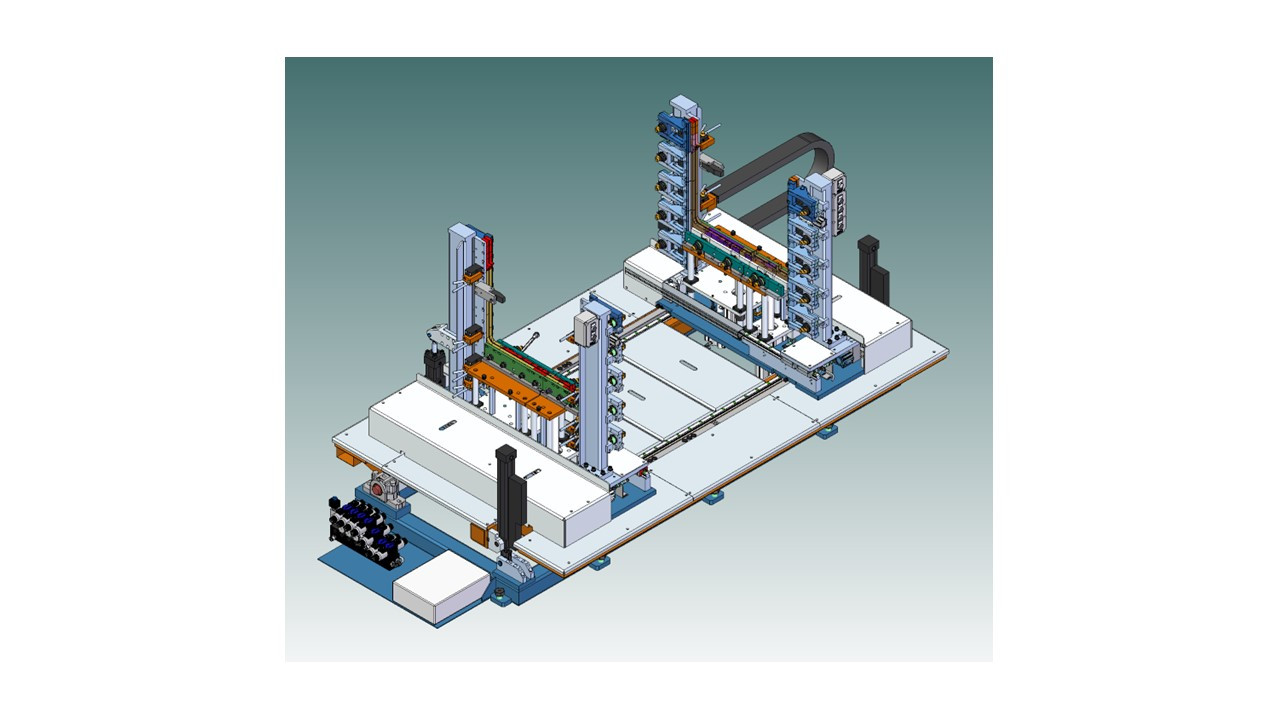

positioner with:

main horizontal rotation axis

secondary rotation axis (orthogonal to the primary)

interface for fixing and electrical-pneumatic connection of the template

equipment with:

connection and fixing interface to positioner

pneumatically moved flap clamping and pressing branches

pneumatic internal expander

mechanical versioning system for managing the 3 different versions of the oven

pneumatic perimeter centering devices

bottom clamping suction cups

slave plc installed on board templates for connection to main plc on electrical panel

pneumatic solenoid valve groups on board

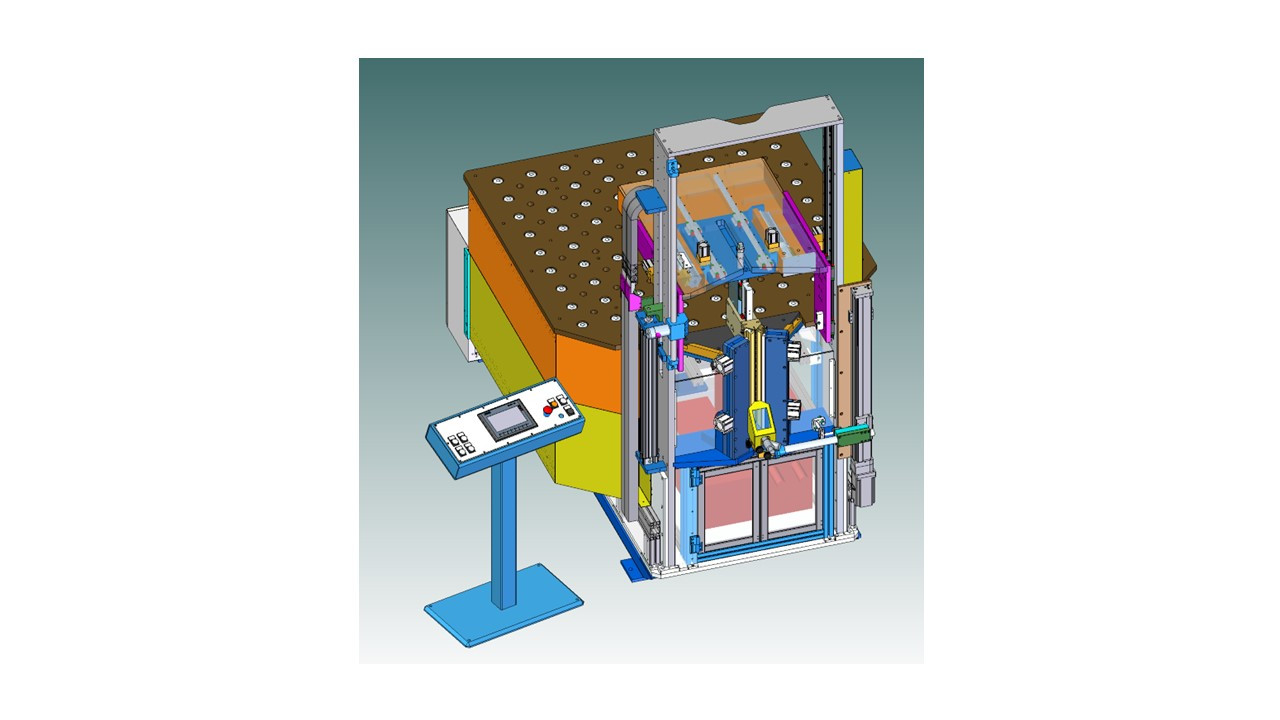

electrical control panel with:

panel on pulpit

safety plc interfaced with welding robot system

control and signalling buttons

touch panel

touch panel from which it is possible to:

select the manual controls individually

view the active alarms

choose the family to be processed

view the status of the plc signals and marker

display the steps of the PLC program of operation

display the status of the mobile unit during versioning

Contact us for more informations

Request information about Robot welding equipment for ovens

Prodotti simili

Welding Jigs and Welding Machines

Welding Jigs and Welding Machines

Oven welding jig

Welding Jigs and Welding Machines

Welding Jigs and Welding Machines

Inox tank welding plant

Welding Jigs and Welding Machines

Welding Jigs and Welding Machines

Case edge welding machine

Welding Jigs and Welding Machines

Welding Jigs and Welding Machines

Machine for welding the tank to the back of a glasswasher

Welding Jigs and Welding Machines

Welding Jigs and Welding Machines

Welding jig for pasta cooker shelf

Welding Jigs and Welding Machines

Welding Jigs and Welding Machines

Manual welding jigs

Welding Jigs and Welding Machines

Welding Jigs and Welding Machines