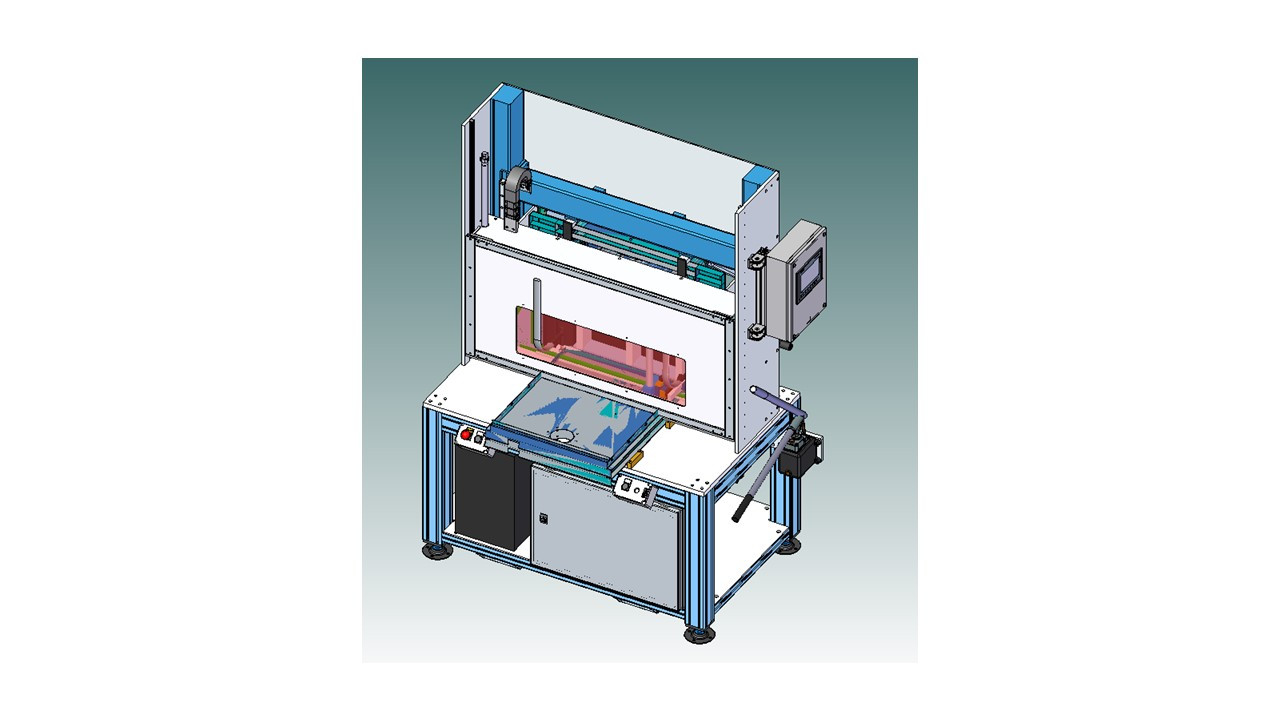

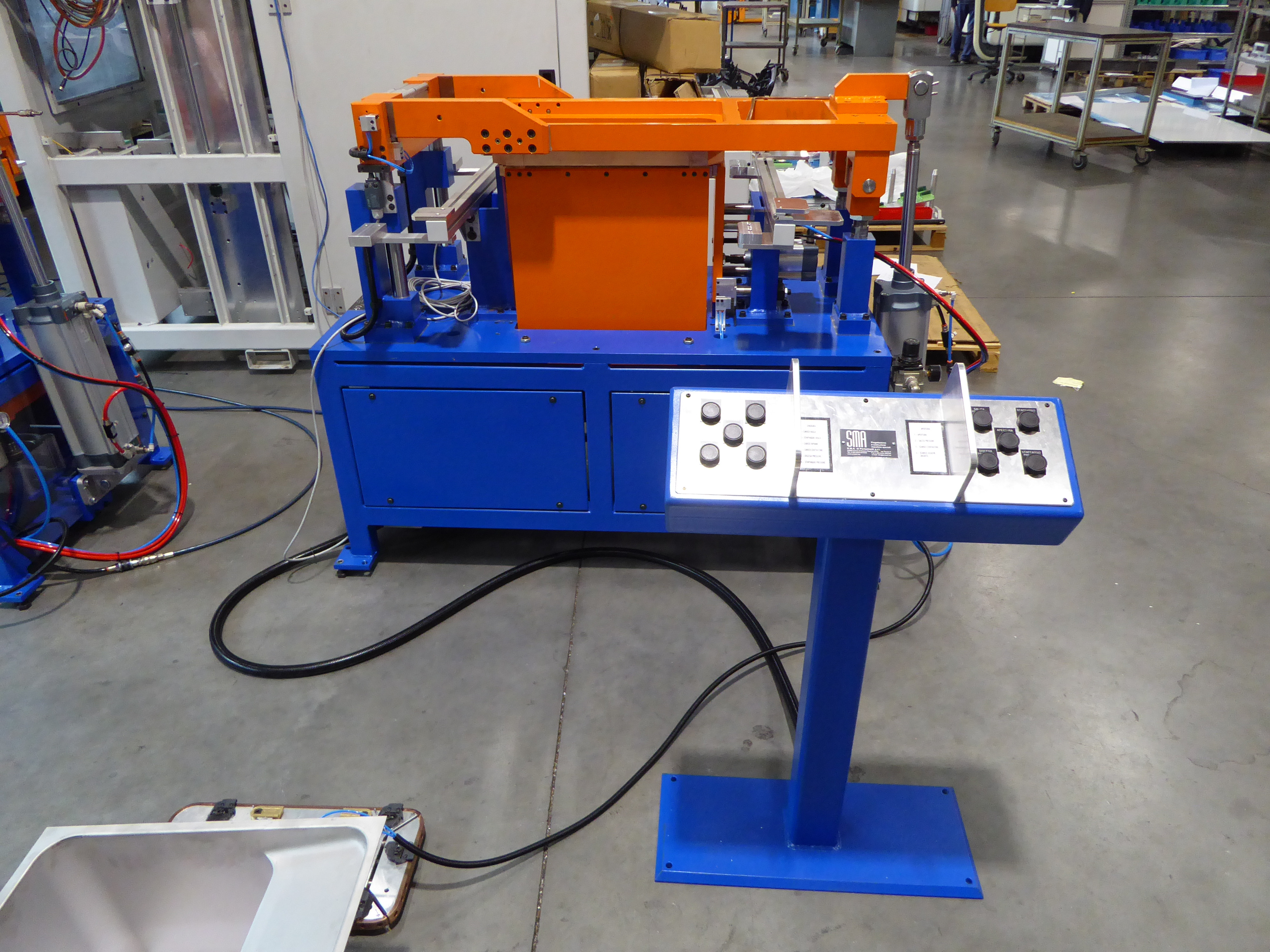

Glass washer cavity welding jig

The system consists of:

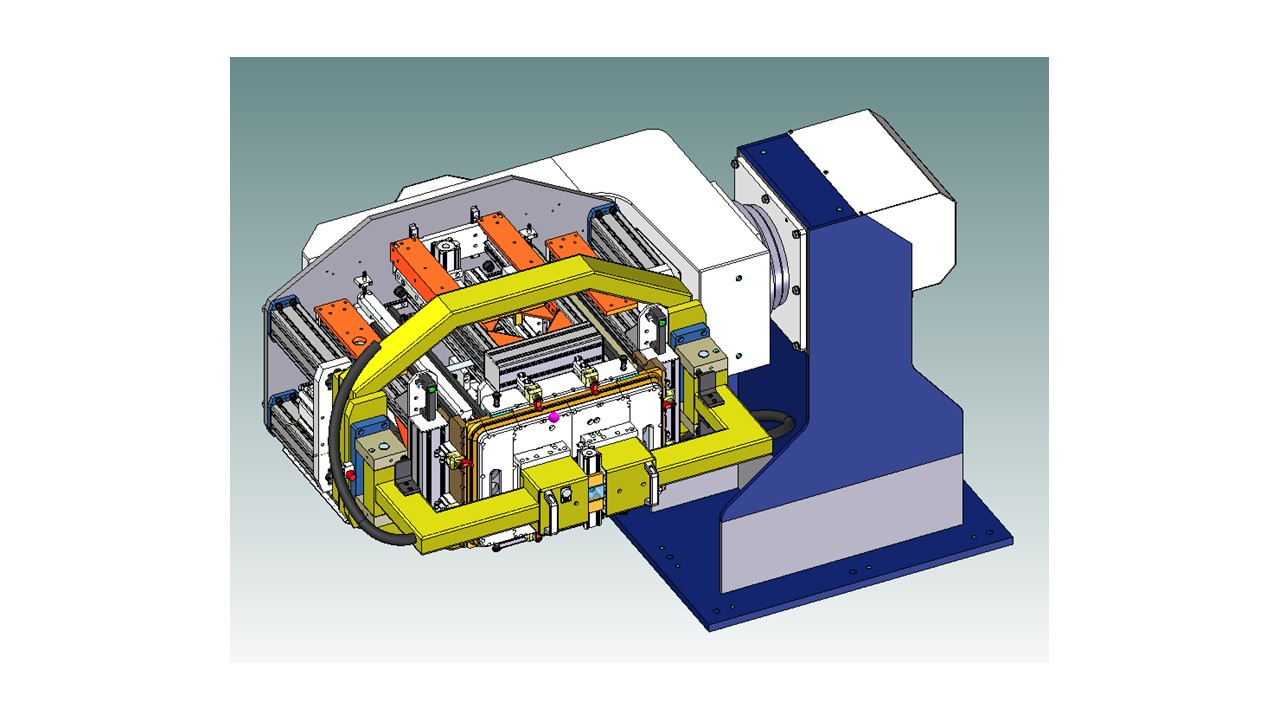

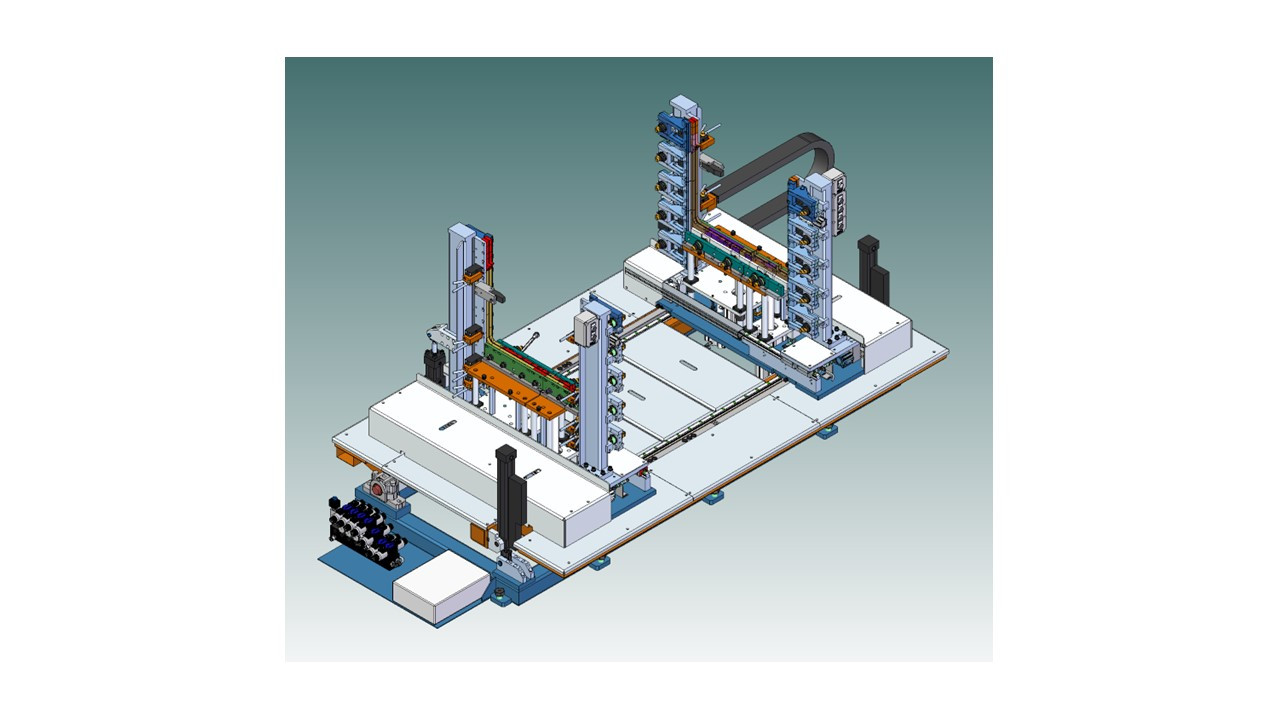

- two-position positioner with:

main rotation axis for rotating the two jigs from the loading/unloading position to the robot welding station and vice versa

jig rotation axes (axes perpendicular to the main rotation axis)

interface plates for semi-automatic fixing and connection of the jigs

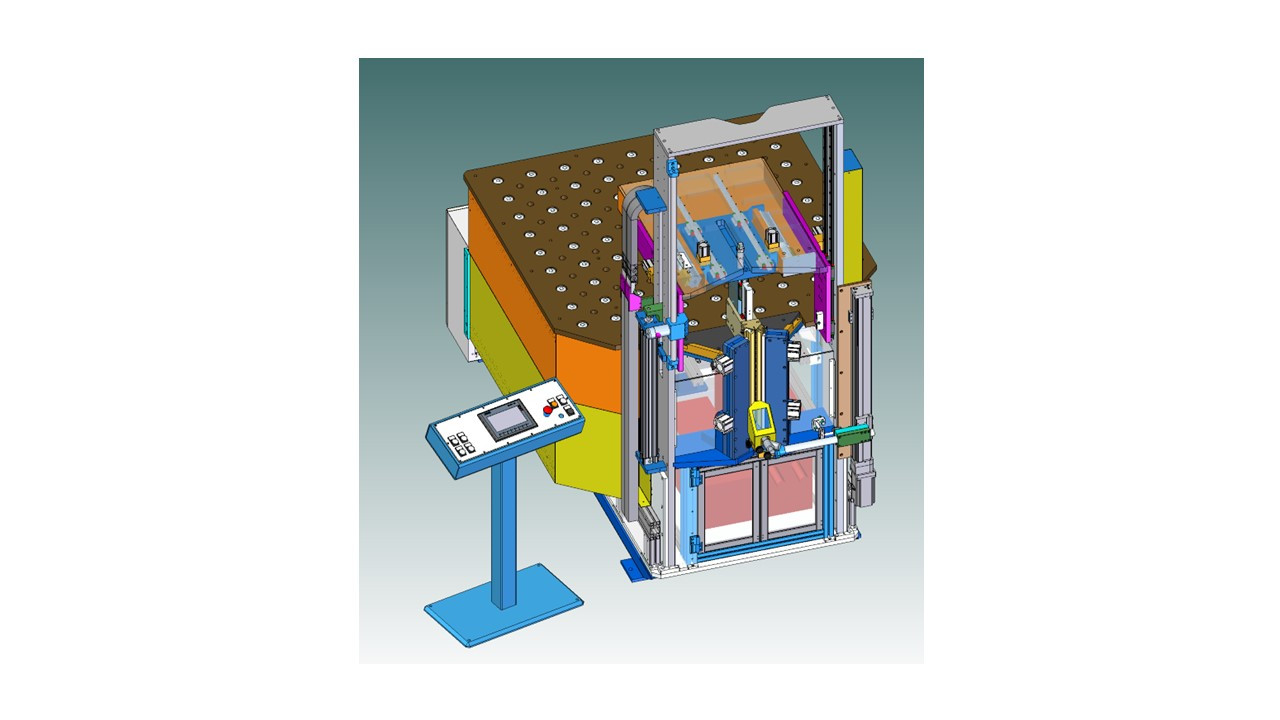

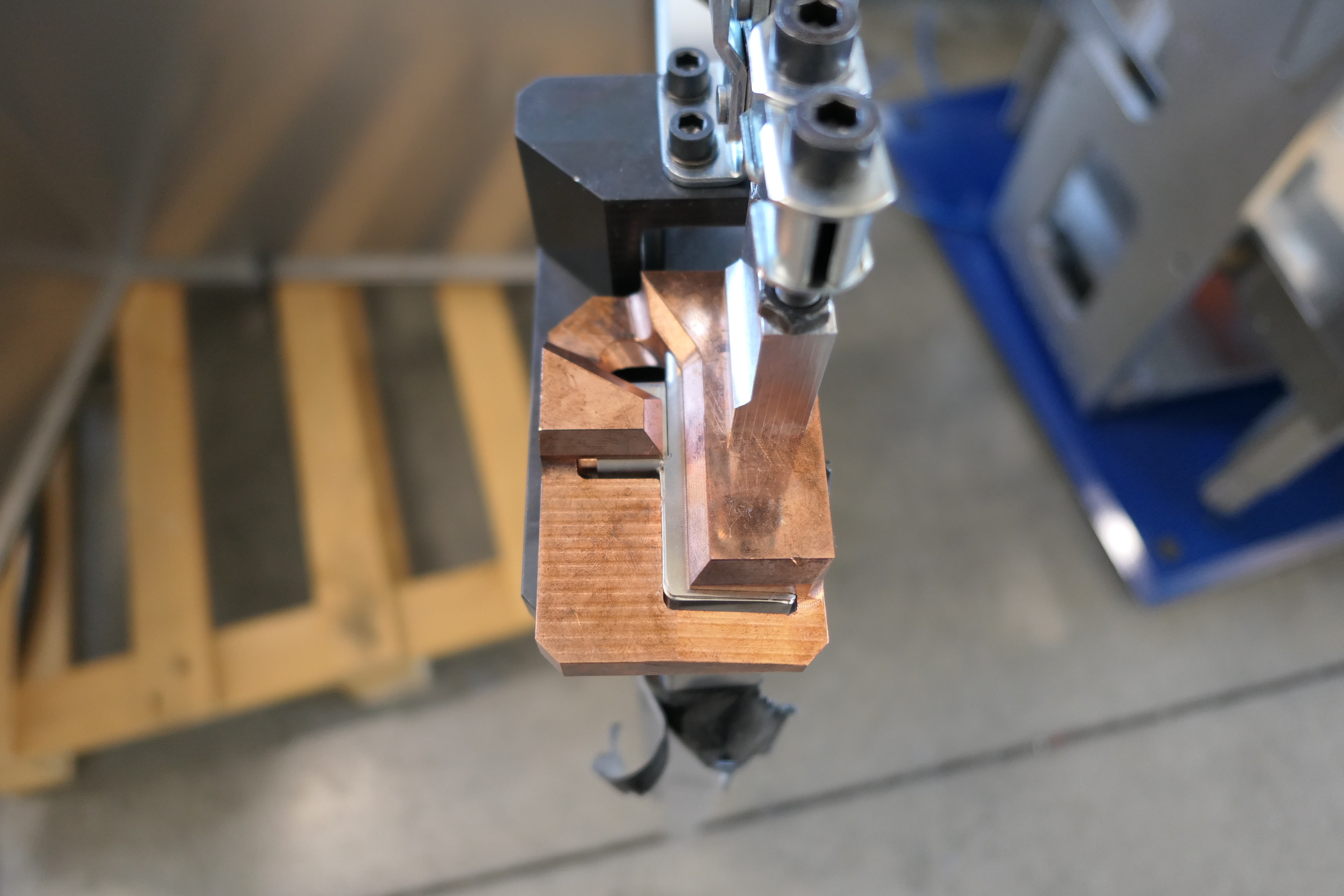

- two welding jigs with:

connection and fixing interface to robot lathe

hydraulically operated clamping and pressing arms

internal pneumatic expander

perimeter pneumatic centering devices

bottom clamping suction cups

slave PLC installed on board the jigs for connection to the main PLC on the electrical panel

hydraulic solenoid valve units on board

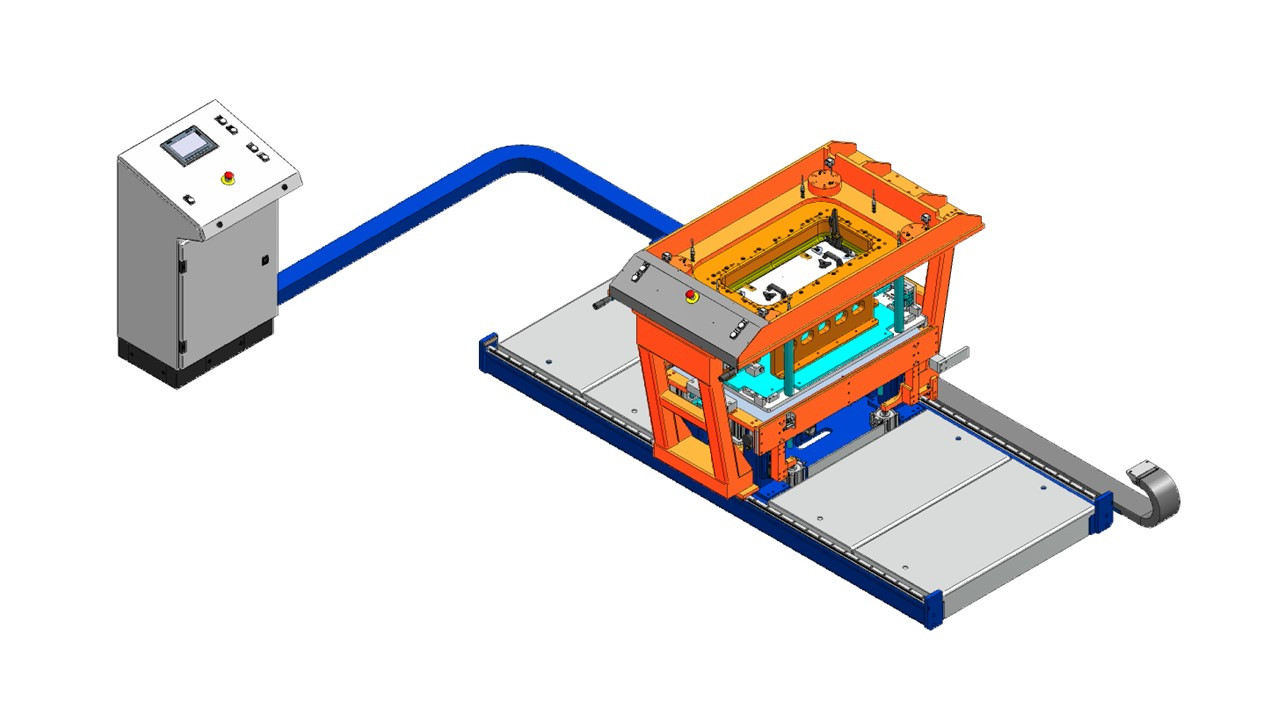

- electrical control panel with:

control panel on console

control PLC interfaced with welding robot system

control buttons and indicator lights

- hydraulic power unit with:

100 l tank

two pumps for separate control of the two jigs

Contact us for more informations

Request information about Glass washer cavity welding jig

Prodotti simili

Welding Jigs and Welding Machines

Welding Jigs and Welding Machines

Robot welding equipment for ovens

Welding Jigs and Welding Machines

Welding Jigs and Welding Machines

Oven welding jig

Welding Jigs and Welding Machines

Welding Jigs and Welding Machines

Inox tank welding plant

Welding Jigs and Welding Machines

Welding Jigs and Welding Machines

Case edge welding machine

Welding Jigs and Welding Machines

Welding Jigs and Welding Machines

Machine for welding the tank to the back of a glasswasher

Welding Jigs and Welding Machines

Welding Jigs and Welding Machines

Welding jig for pasta cooker shelf

Welding Jigs and Welding Machines

Welding Jigs and Welding Machines