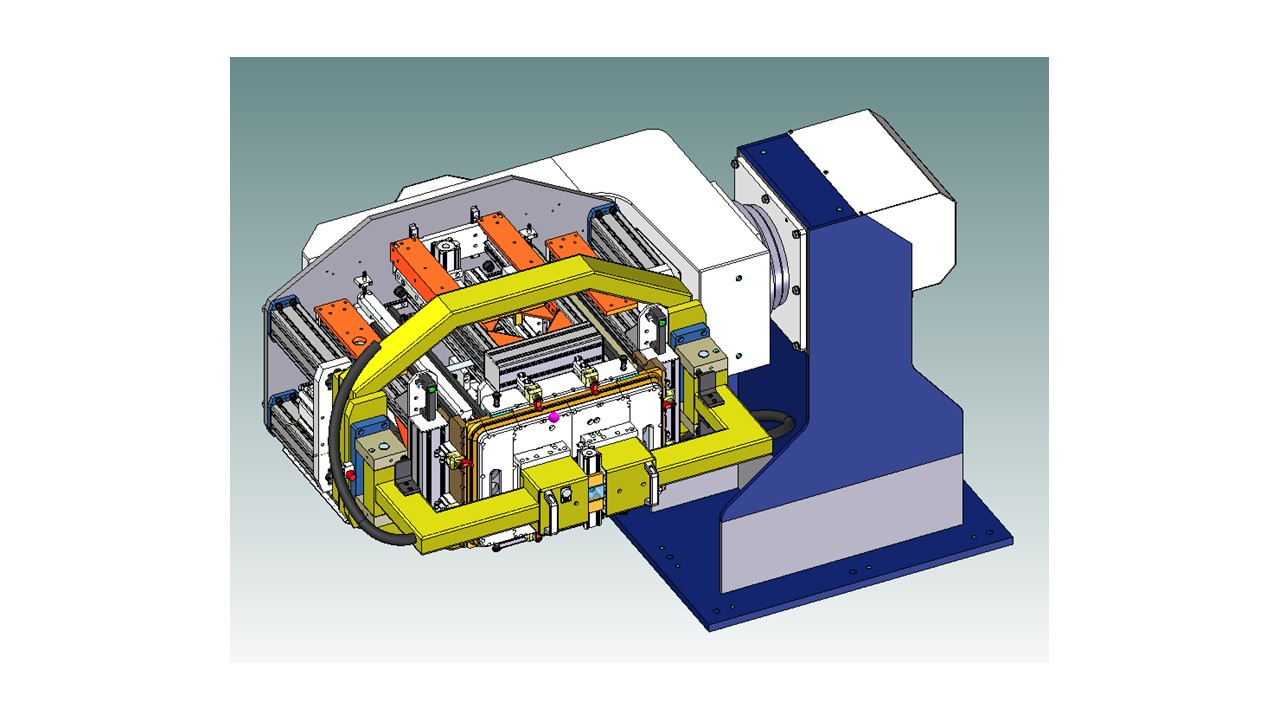

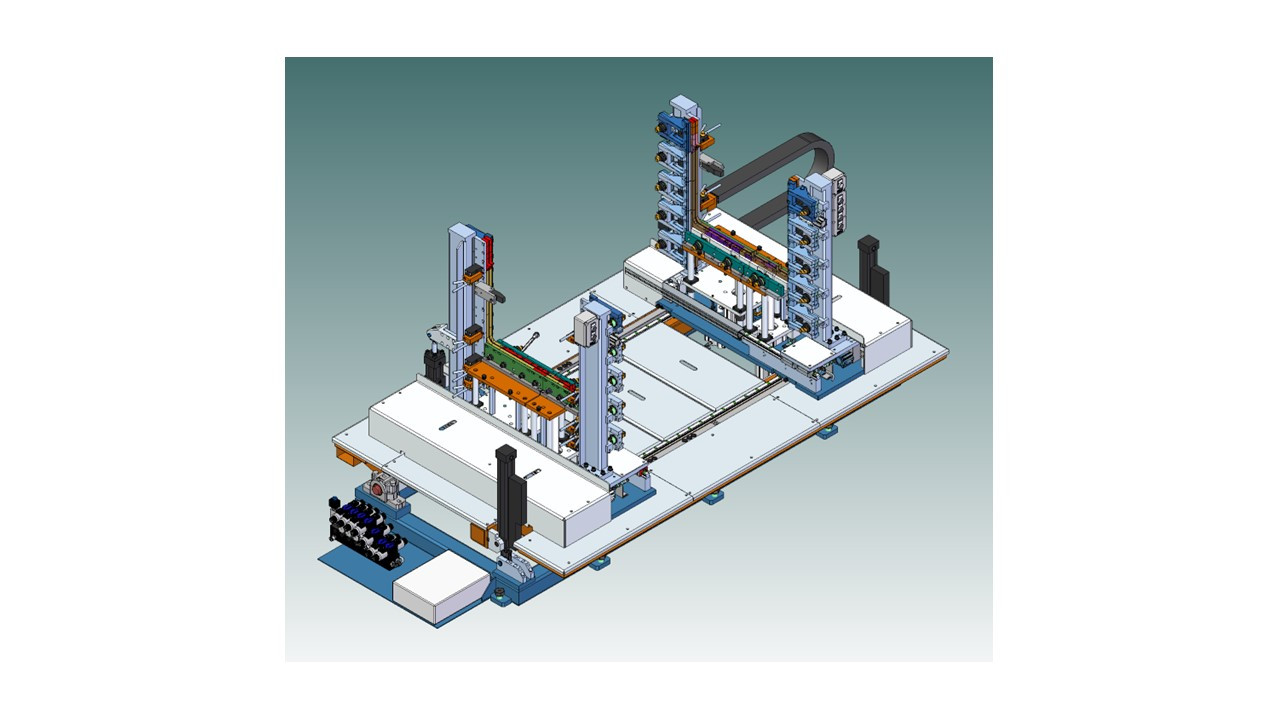

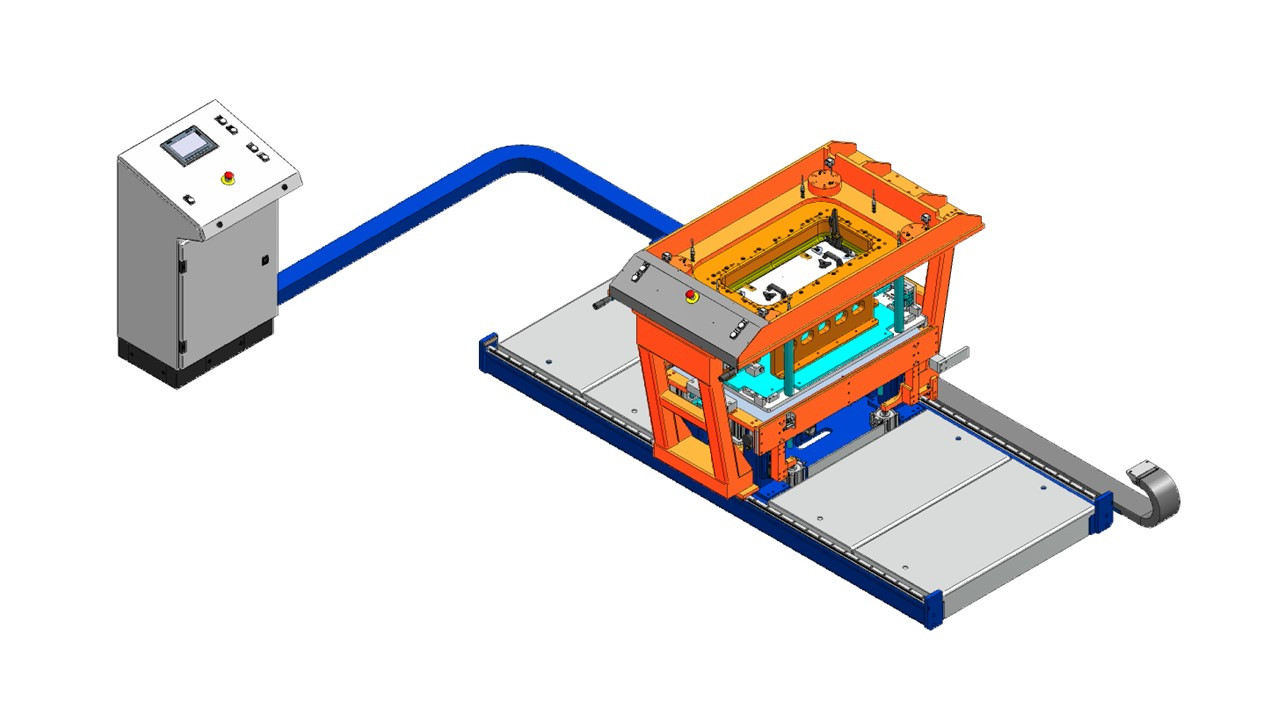

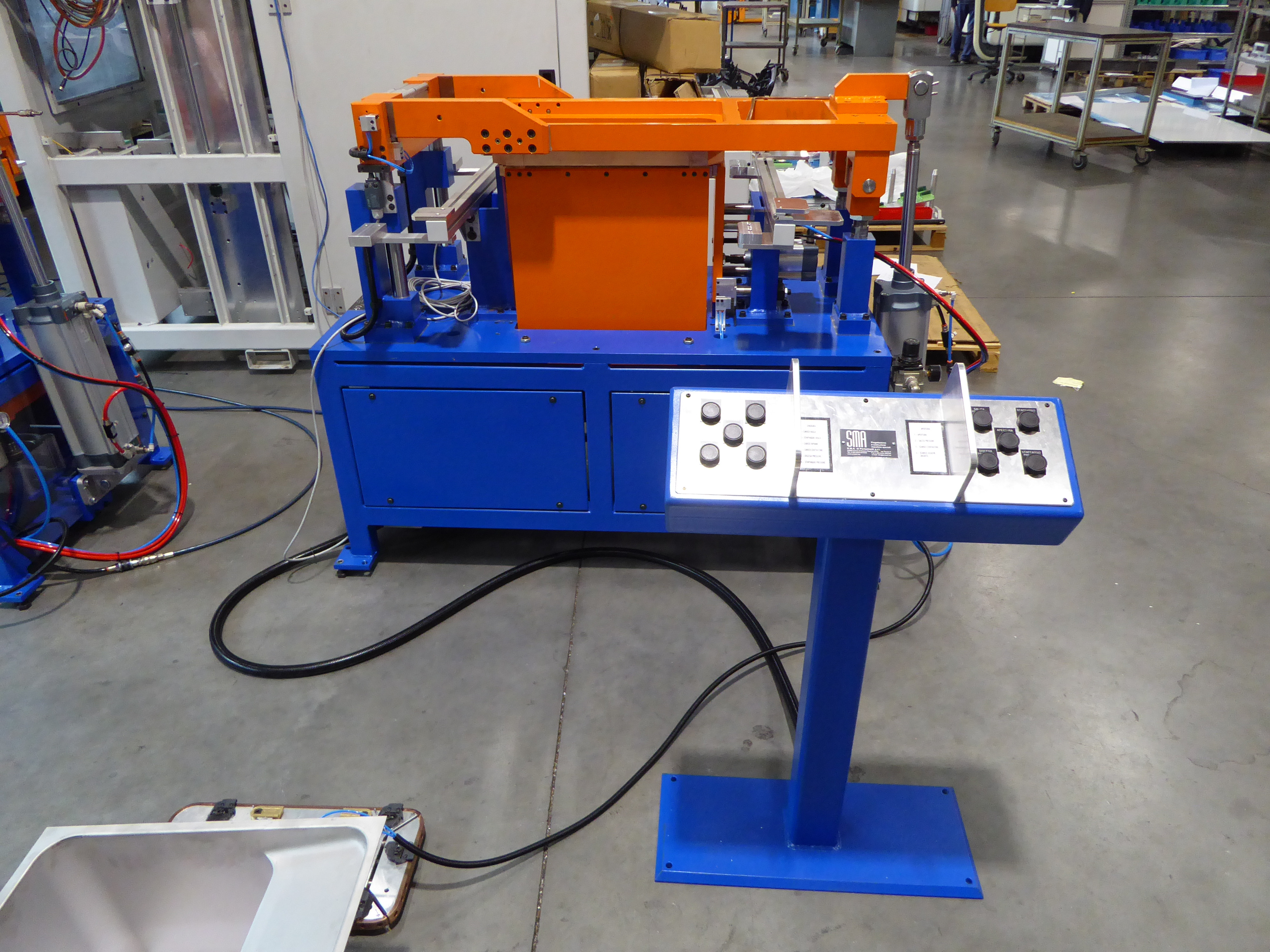

Machine for welding the tank to the back of a glasswasher

The machine carries out the longitudinal weld between basin and backsplash of glasswashers, allowing the processing of different models without the need for tooling or mechanical adjustments between one format and another.

movement of the welding torch via electric axis with brushless motor and dedicated drive system

TIG welding generator

cooling system with chiller

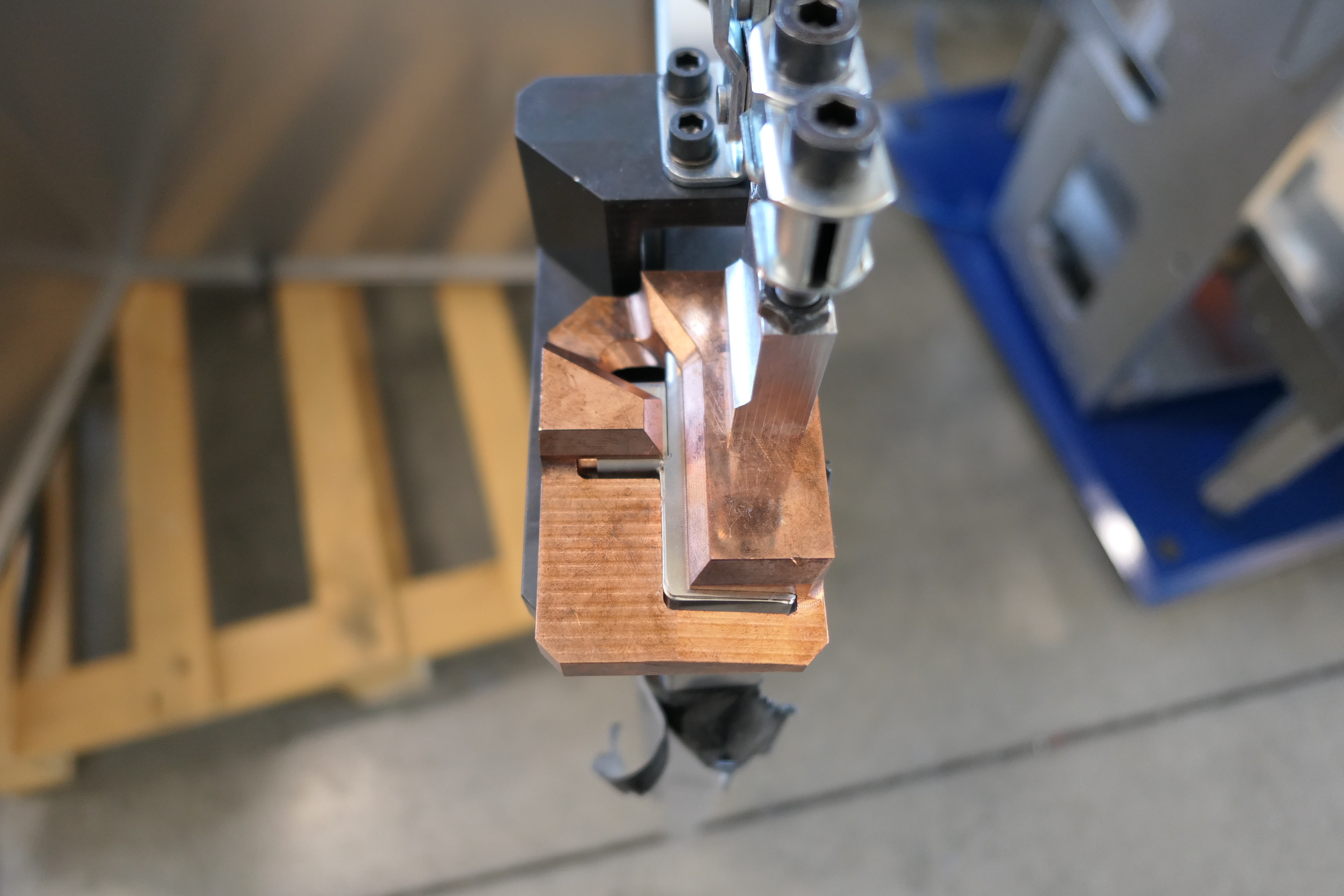

mechanical devices for precise and repeatable positioning of components

pneumatic mechanisms for secure and stable clamping of the elements to be welded

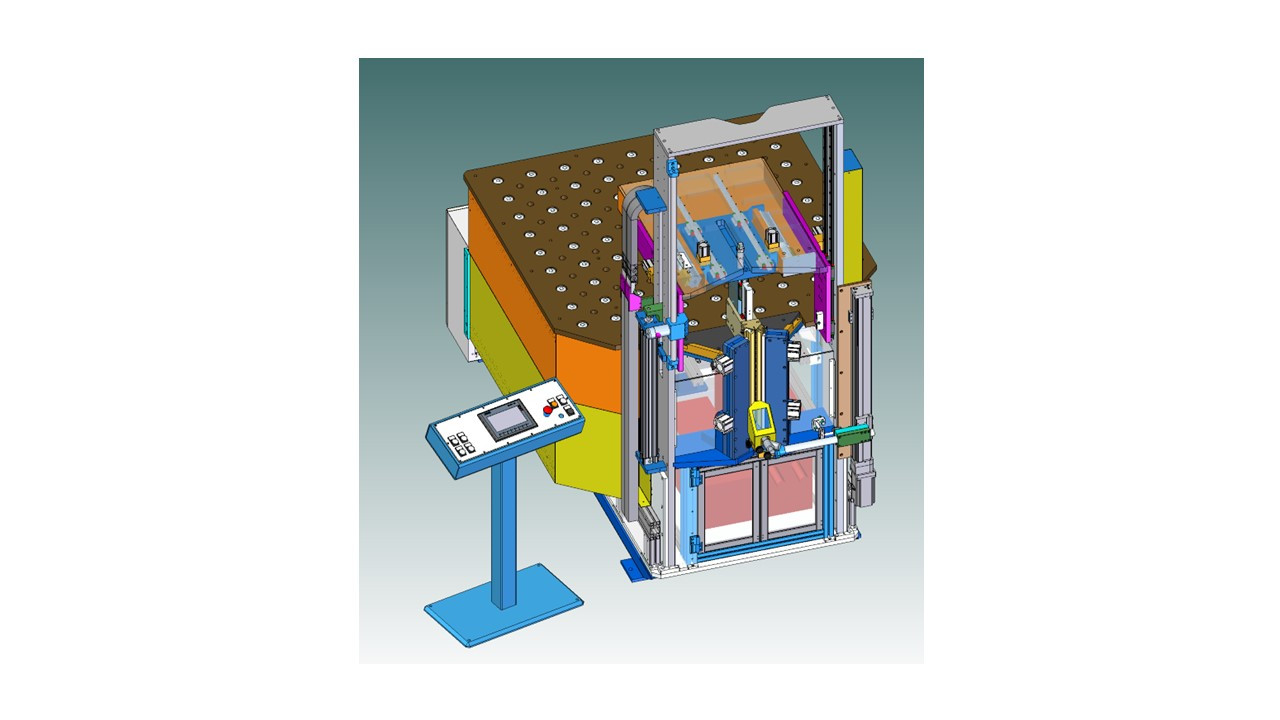

touch panel to display in real time the operating phases during cycle execution, monitor any anomalies found during the test cycle, consult the values of process variables, and manually command the various moving organs of the machine (function enabled with password)

view the various work phases as they occur;

view the anomalies found during the work cycle;

view any functional anomalies;

view and edit the values of different variables;

manually control the various moving parts of the machine (password enabled)

Contact us for more informations

Request information about Machine for welding the tank to the back of a glasswasher

Prodotti simili

Welding Jigs and Welding Machines

Welding Jigs and Welding Machines

Robot welding equipment for ovens

Welding Jigs and Welding Machines

Welding Jigs and Welding Machines

Oven welding jig

Welding Jigs and Welding Machines

Welding Jigs and Welding Machines

Inox tank welding plant

Welding Jigs and Welding Machines

Welding Jigs and Welding Machines

Case edge welding machine

Welding Jigs and Welding Machines

Welding Jigs and Welding Machines

Welding jig for pasta cooker shelf

Welding Jigs and Welding Machines

Welding Jigs and Welding Machines

Manual welding jigs

Welding Jigs and Welding Machines

Welding Jigs and Welding Machines