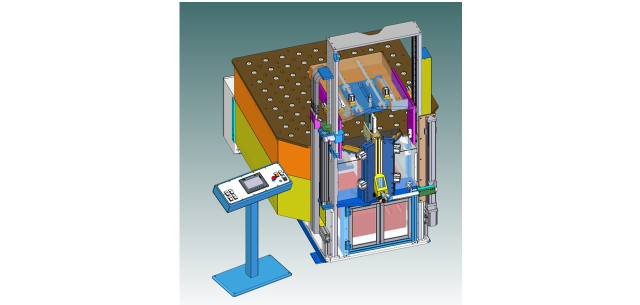

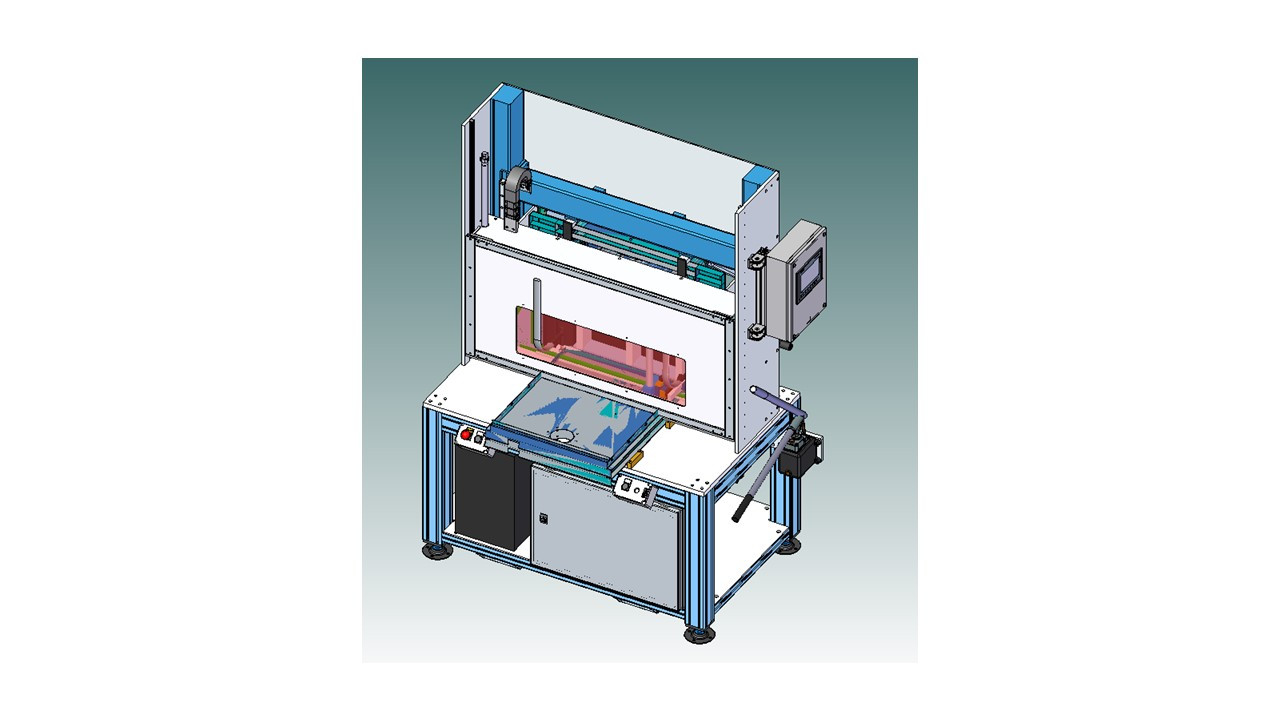

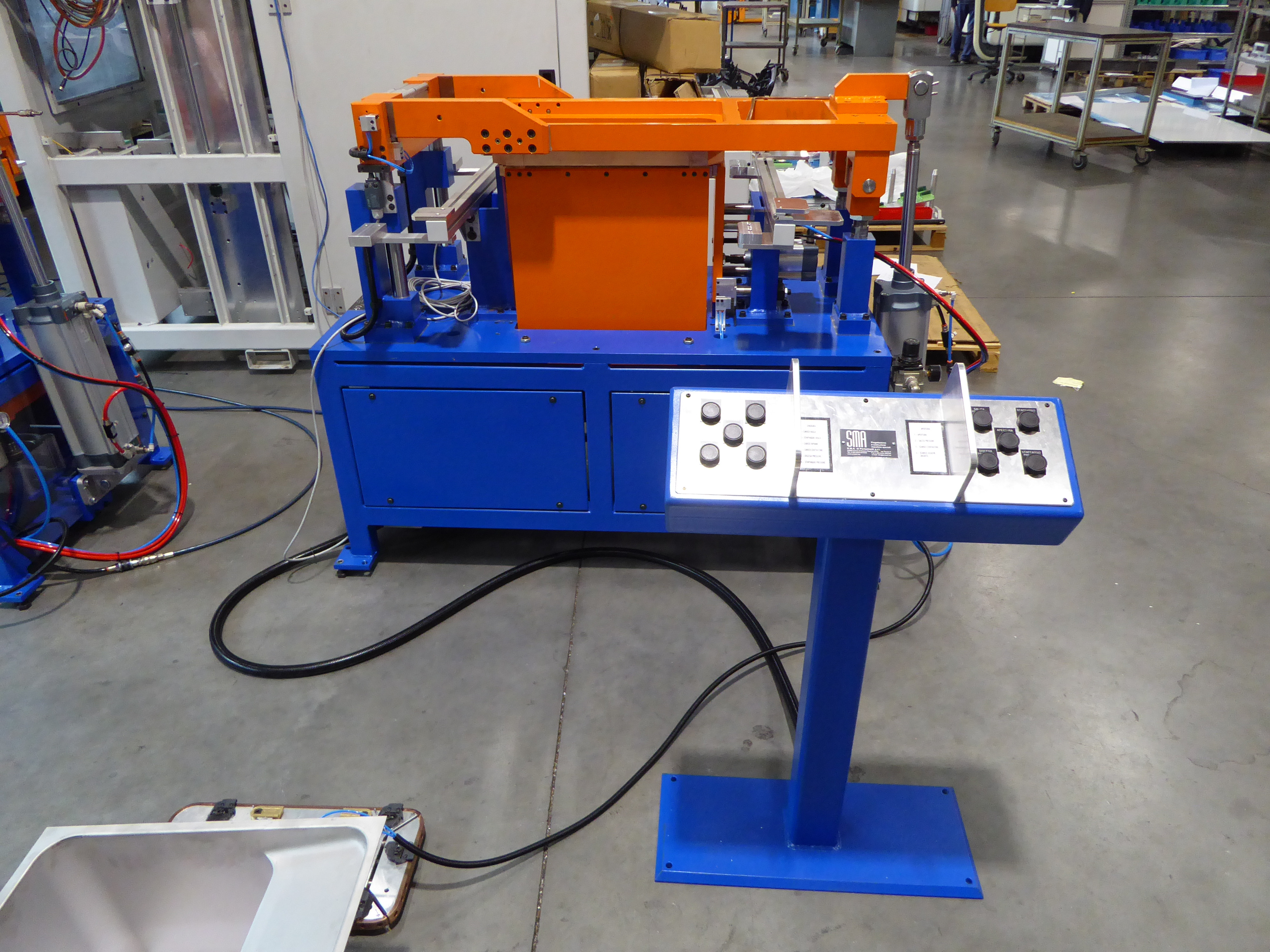

Case edge welding machine

The machine performs TIG welding of the corner edges of stainless-steel cases, ensuring a high-quality aesthetic result and a simple, safe procedure even for non-specialized operators.

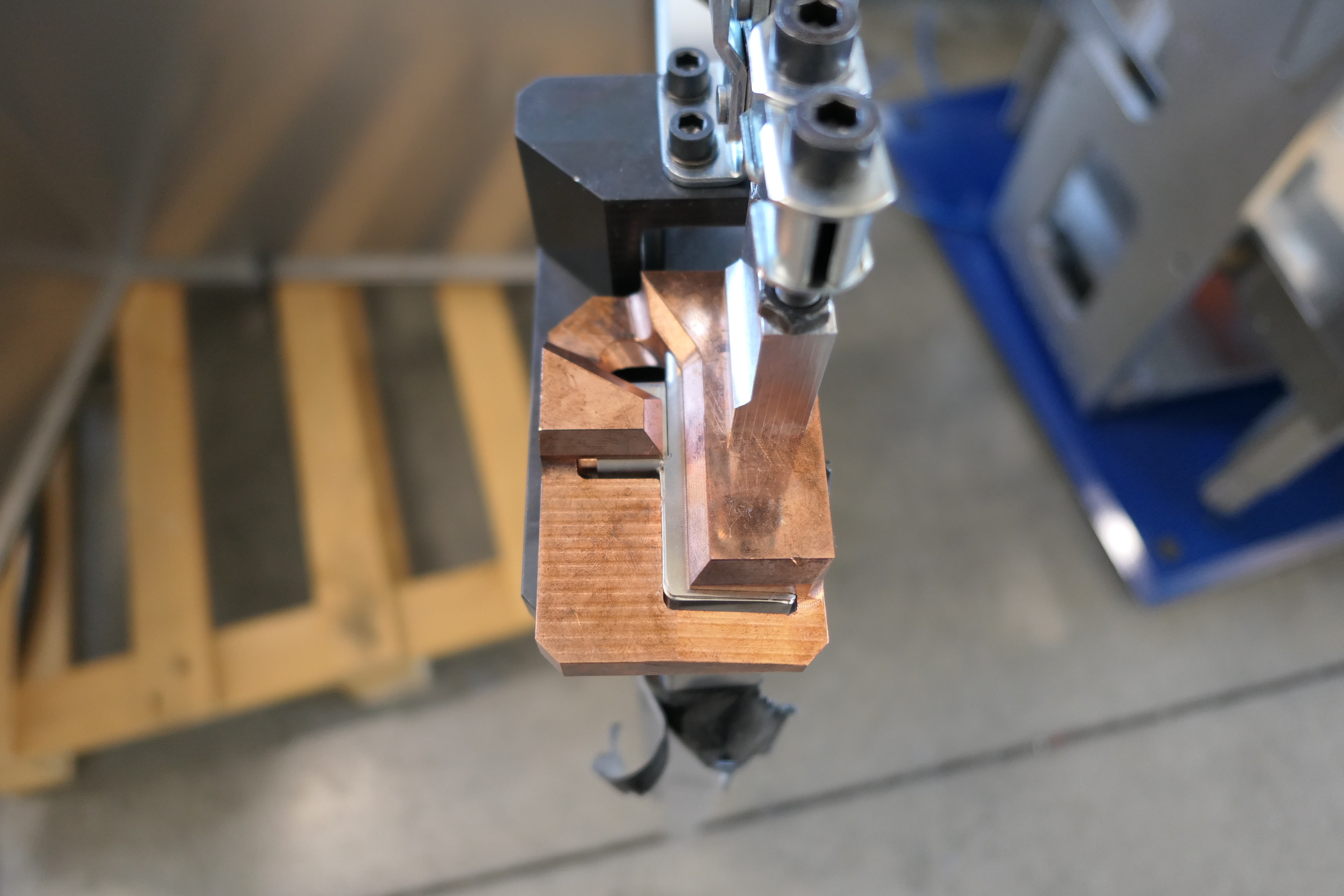

Thanks to a quick setup system, it is possible to weld different case formats efficiently. The heat generated during welding is effectively dissipated via copper supports and a cooling circuit with chiller. Inside the case, the copper support integrates a back-purge gas passage, optimizing the aesthetic result of the weld.

locking and perfect matching of the corner edges thanks to a special mechanical system

quick setup system for internal copper support

plane with load-bearing spheres for simple manual movement of the case

possibility of welding cases from a minimum of 210x180x170 mm up to a maximum of 1800x1200x500 mm with quick guided setup

Fronius welding generator

cooling chiller

electric axis with torch movement drive

micrometric adjustment of the spatial position of the torch

possibility to adjust various characteristic parameters directly from the touch panel

for those who do not require a robotic welding system

for those who want a machine usable even by non-expert personnel

for those aiming to achieve a high aesthetic standard of the welded joint

Contact us for more informations

Request information about Case edge welding machine

Prodotti simili

Welding Jigs and Welding Machines

Welding Jigs and Welding Machines

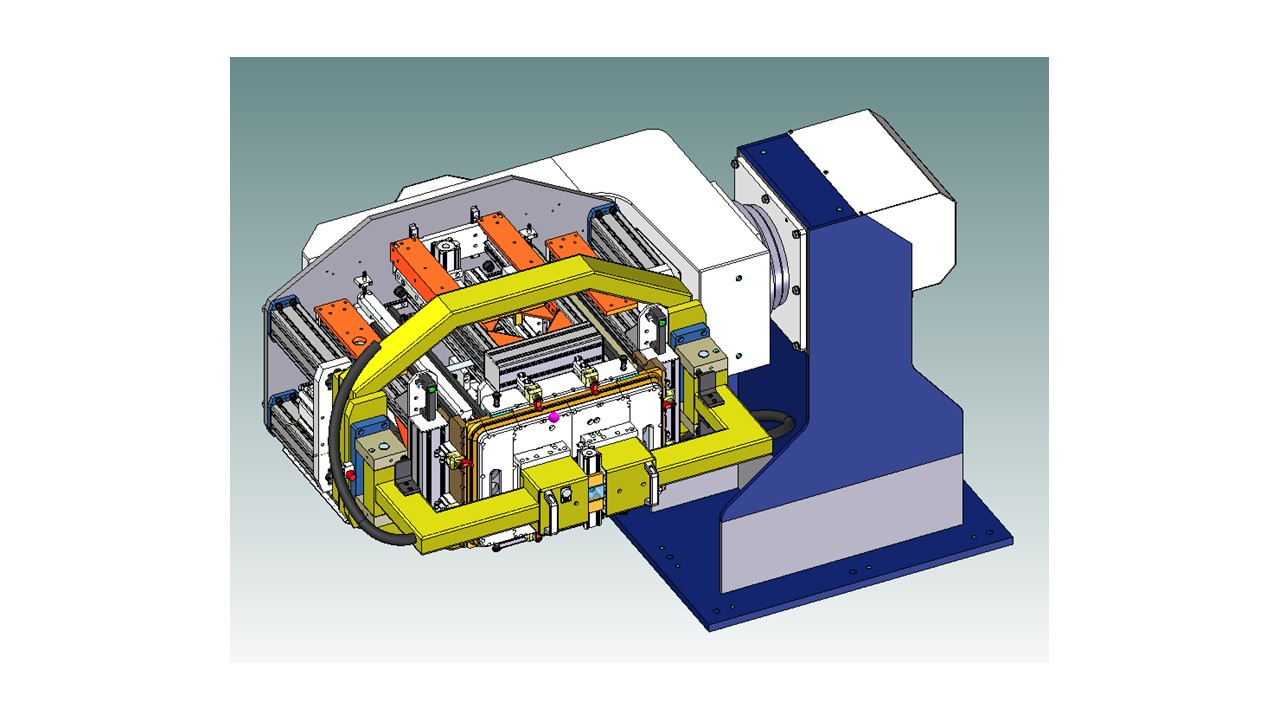

Robot welding equipment for ovens

Welding Jigs and Welding Machines

Welding Jigs and Welding Machines

Oven welding jig

Welding Jigs and Welding Machines

Welding Jigs and Welding Machines

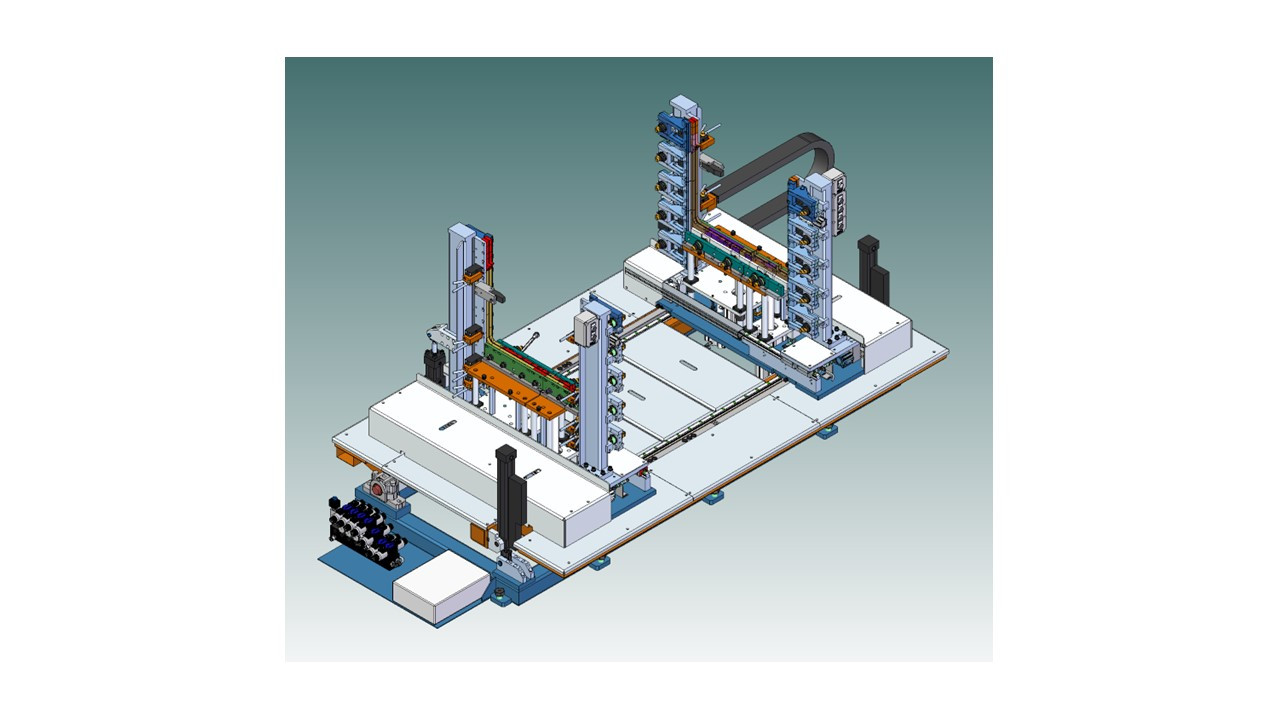

Inox tank welding plant

Welding Jigs and Welding Machines

Welding Jigs and Welding Machines

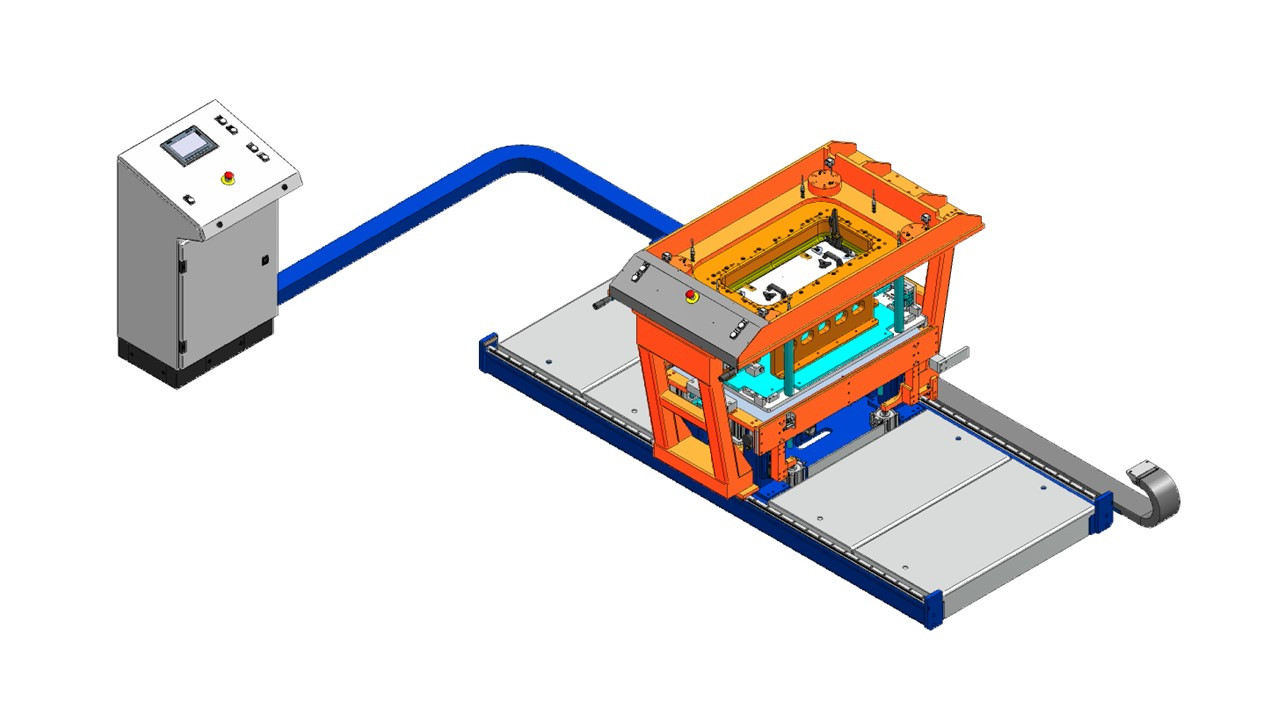

Machine for welding the tank to the back of a glasswasher

Welding Jigs and Welding Machines

Welding Jigs and Welding Machines

Welding jig for pasta cooker shelf

Welding Jigs and Welding Machines

Welding Jigs and Welding Machines

Manual welding jigs

Welding Jigs and Welding Machines

Welding Jigs and Welding Machines