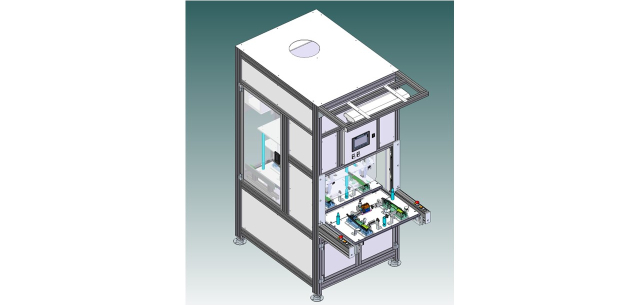

Infrastake riveting machine for PCB fixing pegs

The machine joins plastic components using Infrastake technology, ensuring precise and repeatable riveting. The system is structured to guarantee high standards of reliability, safety, and flexibility in managing the models to be processed.

gantry structure with load-bearing frame made of aluminum profiles

conveyor belt for moving the riveting tool pallets

idler roller conveyor for transporting the entire tool, with possibility of quick versioning

upper plate equipped with electrical and pneumatic interfaces, with dedicated locking system

pneumatic system for actuating the riveting devices

control electrical cabinet with touch-screen operator panel

perimeter guards complete with access doors with interlocked movable guards, controlled by RFID safety sensors

safety barrier for the pallet tool handling area

The touch-screen operator panel is the main interface for managing the work cycle. It allows issuing manual commands, adjusting operating parameters, and viewing all information related to machine status and cycle execution.

Riveting machine for washing-machine dashboard

The machine performs hot riveting of the trim’s studs, ensuring assembly to the aesthetic handle of a washing-machine dashboard. The riveting process is achieved through the combined action of resistance heaters with thermocouple, each controlled via PLC, and pneumatic actuators for pressure and positioning.

Contact us for more informations

Request information about Infrastake riveting machine for PCB fixing pegs